testing the hardness of mild steel|types of hardness testing methods : convenience store Typical densities of various substances are at atmospheric pressure. Density is defined as the mass per unit volume. It is an intensive . See more Vous êtes sur Gupy, le moteur de recherche de l'offre VOD légale.Gupy soutient les plateformes de streaming légal & propose un dispositif de lutte anti-piratage innovant ()

{plog:ftitle_list}

WEBna torcida, em grande estilo. 🖤 Vocês votaram e essa foi a camiseta vencedora da campanha que o Mercado Bitcoin fez para homenagear a nossa torcida. Achei ela linda e vocês? Isso é futuro. É o Vasco mostrando que está sempre à frente e inovando #VascoDaGama #EmuitoAmorInvestido #mercadobitcoin

Low-carbon steel, also known as mild steel is now the most common form of steel because its price is relatively low while it provides material properties that are acceptable for many applications. Low-carbon steel contains approximately 0.05–0.25% carbon making it malleable and ductile. Mild steel . See moreTypical densities of various substances are at atmospheric pressure. Density is defined as the mass per unit volume. It is an intensive . See moreMaterials are frequently chosen for various applications because they have desirable combinations of mechanical characteristics. For structural applications, material properties are crucial and engineers must take them into account. See more

Thermal properties of materials refer to the response of materials to changes in their thermodynamics/thermodynamic-properties/what-is-temperature-physics/”>temperature and to the application of heat. As a solid absorbs thermodynamics/what . See more

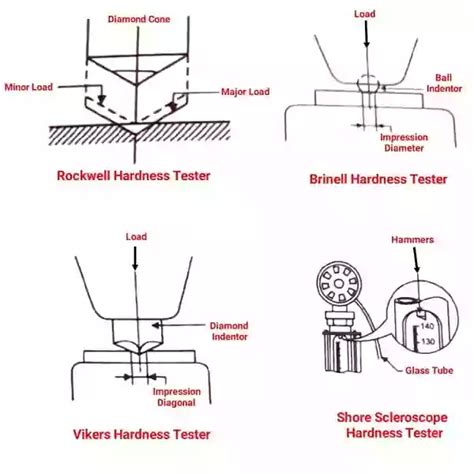

Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Various hardness testing .How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the materials .

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the .

The Rockwell hardness test is a widely used method for determining material hardness, especially in high-volume testing environments, due to its speed, simplicity, and . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. The Brinell hardness scale is a widely accepted measure of hardness in materials. It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. The softer .

Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, . Low carbon steel (or mild steel) is one of the most common types of carbon steel, with a carbon content between 0.04% and 0.30%. Medium carbon steel has a carbon range of 0.31% to 0.60%, and a manganese .1. Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing 3. What are the advantages and limitations of Rockwell method of hardness testing 4. Where are Rockwell hardness test and Brinell hard test employed 5.

Learn more about material hardness testing. How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . To increase the hardness of the steel alloy. Mild steels (1045, A36) Alloy steels (4140, . Destructive testing and hardness measurement of resistance stud welded joints of ASTM A36 steel . Table 1 gives the chemical composition of ASTM A36 mild steel and Table 2 shows the mechanical . Brinell hardness. The Brinell hardness scale is a widely accepted measure of hardness in materials. It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. The softer the material, the deeper the ball will penetrate and vice versa. The next step is to take a measurement of the diameter .

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. . Brinell Hardness Number; Soft brass: 60: Mild steel: 130: Annealed chissel steel: 235: White cast iron: 415: Nitrided surface: 750: Steel Hardness versus Strength. Steel Hardness versus Strength; Brinell While mild steel has a lower tensile strength than other carbon steel types, it is more pliable and easier to form. You can also harden mild steel with various treatment processes. Mild steel is machinable and weldable, which aids in its usefulness for most applications. Common uses of mild steel include: Building construction; Pipelines

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is . The surface hardness of mild steel can be increased through heat treatment processes like carburizing. This material has moderate strength but as it is cheap and easy to shape, hence, most of the products are of mild steel. Material testing is necessary to determine its mechanical properties and behaviour.In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically. Used for materials with a coarse or inhomogeneous grain .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Mild steel (tc=0.2%) annealing: 60: Precipitation hardening: 170: Bearing steelAluminum alloy (A-Zn Mg Cu) normalizing: 120: cold rolling: 200: Mild steel (tc=0.2%) normalizing: 200: Quenching (830 ℃) 900 .The Jominy test involves heating a cylindrical steel test piece to an austenitizing temperature (~980°–1010°C) and quenching (cooling) from one end, with a controlled and standardized jet of water. After quenching, the hardness is measured at intervals taken from the quenched end. . Hardness testing of welds can be performed on any .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

This hardness testing involves applying a known load to a spherical indenter, typically made of hardened steel, although a tungsten carbide ball may be used for harder materials. The diameter of the resulting .The effect of carbon doping contents on the microstructure, hardness, and corrosion properties of heat-treated AISI steel grades of plain carbon steel was investigated in this study. Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of .

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . Hardness testing is qualitatively and quantitatively discussed with particular references to the various types of hardness tests. Impact testing is also explained, including the mathematical relationship to calculate the impact energy. . The stress-strain curve, as obtained from the tensile test of a mild steel (AISI-1020) sample, is shown in .

The main purpose of this report is to study the mechanical properties and failure mode of mild steel. Three types of standard tests i.e. tensile test, impact test, and hardness test were conducted on the standard specimens of mild steel. From the tests, results were obtained; Tensile strength, Impact strength, and hardness were calculated. Learn about mild steel including its definition, compositions, advantages, disadvantages, applications, environmental impact of mild steel, and the difference between mild steel and stainless steel. . SSC GK PYP Mock Test Series (20k+ Questions) [With 75 Days Hard Challenge] . Alloying elements, such as chromium can increase mild steel's . The most common method for measuring the hardness of mild steel is through the Rockwell scale. The Rockwell Scale measures hardness using three different scales (A, B and C), which range from softest (0) to hardest (100). For example, mild steel typically scores between 50-90 on the Rockwell C scale, which means it can be quite hard depending .All testing equipment must be as non-destructive as possible. Testing equipment needed easy implementation. It allowed easy training and supervision of operators. Testing personnel had understandable, written procedures to follow. Test results had valuable information users needed. The Rockwell hardness testing method fulfilled every requirement.

There are 7 main types of hardness testers. Hardness testing is the procedure of testing the hardness characteristic of a material so properties such as strength, wear resistance, and ductility can be determined! Product Category . Mild steel: 120HB; 18–8 (304) stainless steel annealed 200 HB; Hardox wear plate 400-700 HB; Hardened tool .Mild steel has a relatively low tensile strength, but it is cheap and easy to form; surface hardness can be increased through carburizing. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of . The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation.

types of hardness testing methods

steel hardness testing methods

standard hardness test methods

WEB360p. Novinha safada chupando e tomando leite na boca. 66 sec Bruniin257 - 1080p. Hoje a minha buceta só queria leite dentro. 9 min Novinha Insaciavel - 4.3k Views - 720p. .

testing the hardness of mild steel|types of hardness testing methods